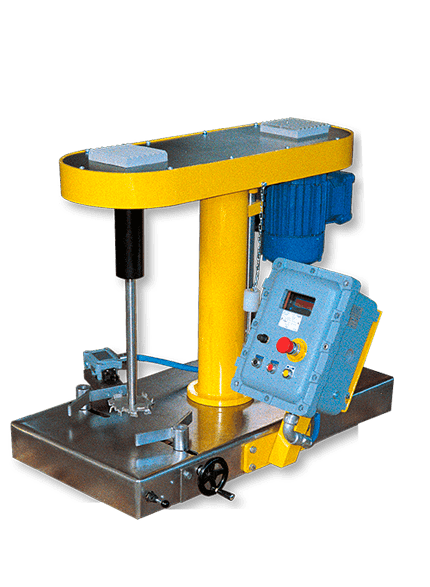

LAB DISPERSERS WITH ELECTRONIC SPEED CHANGE

CONSTRUCTION FEATURES

CONSTRUCTION FEATURES

- Metal structure

- Vessel locking unit adjustable with side clamps operated with hand crank

- BELLOWS safety, including plastic and/or aluminium lid

- Hydraulic lifting with piston and air-operated control levers

- Lifting piston inside bearing column

- High-build chrome-plated stirring shaft

- Trapezoid belt and pulley drive (1:1 gear ratio)

- Cowless AISI 304 stainless steel or chrome-plated impellers

- Inverter control

- Heavy-duty or explosion-proof motor with thermistors

- Safety systems and CE mark

FUNCTIONS

All electric controls of the Disperser are placed on the Inverter front panel or, depending on the version, on the front panel of the explosion-proof control console.

The Disperser head housing the motor can be lifted manually by acting on two side levers: the first one allows compressed air to flow into the pneumatic circuit, while the second one allows the Disperser head to be either raised or lowered.

The head housing the motor can also be locked mid-way by the automatic tripping of safety valves. The vessel side clamps are adjustable for positioning vessels of different diameters.

OPERATION AND MAINTENANCE

- Low energy consumption: power consumption depends on the power actually supplied by the Inverter by setting the power-knob

- Low noise

- Easily accessible and easy-to-use controls

- Easily replaceable vessels even with different diameters

- All main components are surface-mounted.

- The standard (non explosion-proof) version is pre-wired for direct connection to the mains.

SAFETY SYSTEMS

- If the Disperser head is raised during operation, impeller rotation is blocked by a magnetic sensor.

- Safety limit switch on one of the vessel clamps blocks impeller rotation when the vessel is not properly positioned.

- Bellows safety system prevents any contact with the operating stirring shaft, while the lid prevents any accidental contact with the propeller.

ALTERNATIVE VERSIONS

- Explosion-proof control console

- Electric panel with Inverter in IP 55 enclosure

- Rotor with Teflon or similar other material grinding disks

- Double wall vessel for cooling

- 1:2 gear ratio

- Installation of motors of up to approx. 6000 rpm