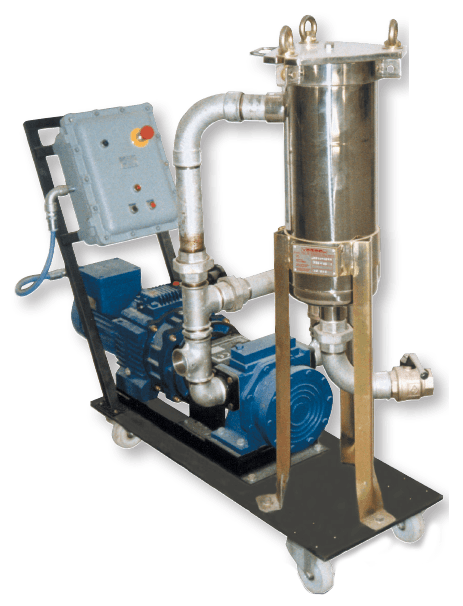

MOBILE FILTER UNITS

CONSTRUCTION FEATURES

CONSTRUCTION FEATURES

- Basic metal load bearing structure

- Pulling handle

- Fixed and rotating wheels for easy movement

- Command platform on board machine

- Positive displacement motor pump with mechanical change gear

- Variation of the number of pump revolutions and therefore the flow rate via hand wheel placed on the body of the pump change gear

- Stainless steel interchangeable sack type static filter

- Filter/pump pipe fitting with curves, "tee" connectors and manual ball valves.

FUNCTIONS

The Mobile Filter Unit, as well as being easy to move and therefore able to be positioned very near its direct use, already has its own control panel so it is sufficient to connect this panel to the mains power network to be able to turn on the unit.

Moreover, if for any special reason it is not necessary to use the filter drum the existing tubing can be disconnected, excluding the filter, thus transforming the unit into a normal mobile pump.

The degree of filtration (Micron) of the filtering sack and the type of product to filter determines the optimum flow rate that must be adjusted as a consequence.

The filter/pump pipefittings also mean it is possible to by-pass the pump itself, i.e. recycling the product if the flow of this towards the filter should slow down.e.

OPERATION AND MAINTENANCE

The commands are all on the front hatch of the command platform, so they are easily accessible.

The pressure switch is on sight on the filter/pump connecting tubes.

Maintenance operations are basically cleaning the inside of the pump body and inside the drum and the filter sack.

In the event the product spurts out too quickly from the filter drum, very probably the filter sack inside the drum has broken, so the flow towards the exit is no longer slowed down by the filtration taking place.

- Check that the filter sack is undamaged every time it is cleaned and/or washed.

- Check that the pipefittings, the manual ball valves and the pump are leak proof.

- Periodically control the oil level of the mechanical change gear.

- Keep the front panel of the command platform clean.

- Clean the inside of the pump with special liquids, being careful of any toxicity in them.

ALTERNATIVE VERSIONS

The Mobile Filter Unit comes in two different models:

The Mobile Filter Unit comes in two different models:

the first normal industrial and the second explosion-proof/flameproof (ATEX).

Normally the pump installed in the Mobile Filter Unit has an approximate flow rate of 100 revolutions equal to 2.2 mc./h, but obviously it is possible to use pumps with different flow rates.

The filter drum and subsequently the internal filter sack as well, if not expressly specified, is supplied with the height of the cylindrical section equal to around 600 mm but other sizes can obviously be used.

The Mobile Filter Unit can be equipped with a block pressure switch of the pump to stop it running where the internal pressure of the piping and the filter is over the established limit.

The Mobile Filter Unit can come with a completely pneumatic diaphragm pump; in this case the command platform is no longer necessary as the pump is supplied only pneumatically.

The pneumatic pump operates and stops by hand turning a small manual ball valve placed on the pump body which will have the Rilsan compressed air supply tube connected to it.

The flow rate of the pneumatic diaphragm pump can fluctuate according to the pump model that is installed in the Mobile Filter Unit; normally these flow rates oscillate more or less between 80 and 240 litres per minute.