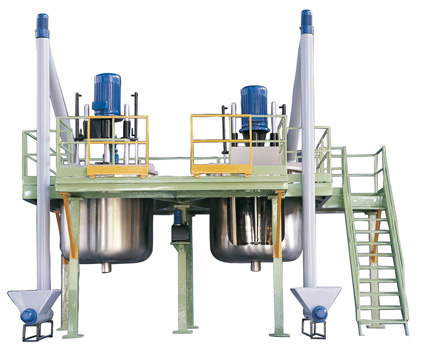

COUPLE OF STAGE-MOUNTED DISPERSERS

CONSTRUCTION FEATURES

CONSTRUCTION FEATURES

- Metal bearing structure in carbon steel sections and tubing

- Independent access ladder, with rails and feet-support, and front sliding rail

- Two AISI 304 stainless steel mixing vessels with three 120° support frames

- Carbon steel and/or AISI 304 stainless steel self-bearing lid with proper couplings for powder and fluid loading, and dust extraction pipes

- Lifting of motor heads by power unit and hydraulic distributor that can be operated with two different movements to ensure against accidental starting

- Lifting piston with check valves and flow control

- High-build chrome-plated stirring shafts

- Direct drive

- Cowless Aisi 304 stainless steel or chrome-plated impellers

- Switch board with Inverter control with disturbance filter

- Control panel of standard or explosion-proof type

- Heavy-duty or explosion-proof motor with thermistors

- Two gearmotor-driven scrapers (approx. 8 rpm)

- Mobile lid section for vessel access with safety limit switch to ensure that the machine is not started when the lid is up

- Safety systems and CE mark

FUNCTIONS

All electric controls and warning devices are placed on the Control Panel of the Disperser couple.

The hydraulic-operated head lifting distributor is located on the machine body: it must be operated after pressing the ON push-button of the hydraulic power unit motor on the Disperser control panel.

The Control Panel also features: the potentiometer for continuous stirring shaft speed adjustment, digital rev-counter with display, the ON-OFF-RESET push-buttons for Inverter control and the EMERGENCY button. The Switch Board with the Inverter features the following controls:

- Power switch to set the machine on

- Thermal cut-out, mains voltage, thermistor protection lights

- Emergency button

OPERATION AND MAINTENANCE

- Low energy consumption: power consumption depends on the power actually supplied by the Inverter by turning the power-knob

- Low noise

- Easily accessible and easy-to-use controls

- Easy access to mixing vessels for maintenance and/or replacement of vessels, of scrapers or just for cleaning

- Easy access to the power unit, normally located under the feet-support of the Disperser Couple Stage and anchored on a proper bracket on the support leg between the two mixing vessels.

ALTERNATIVE VERSIONS

- Flat or convex Aisi 304 stainless or carbon steel vacuum-tight lid, vacuum-pump connections, connections for fluid loading, inspection port.

- Dual Inverter power supply (one single Inverter in the basic model)

- Lifting with two hydraulic power units. This feature, together with the dual Inverter, makes the two Dispersers totally independent of each other.

- Automatic and/or manual powder and fluid loading

- 6 and 8 pole motor (4 pole motors are normally employed

- Continuous motor cooling at low duty with servoventilation

- Head lifting/lowering with Control Panel push-buttons and solenoids on the hydraulic power unit (instead of a hydraulic distributor installed on the machine)