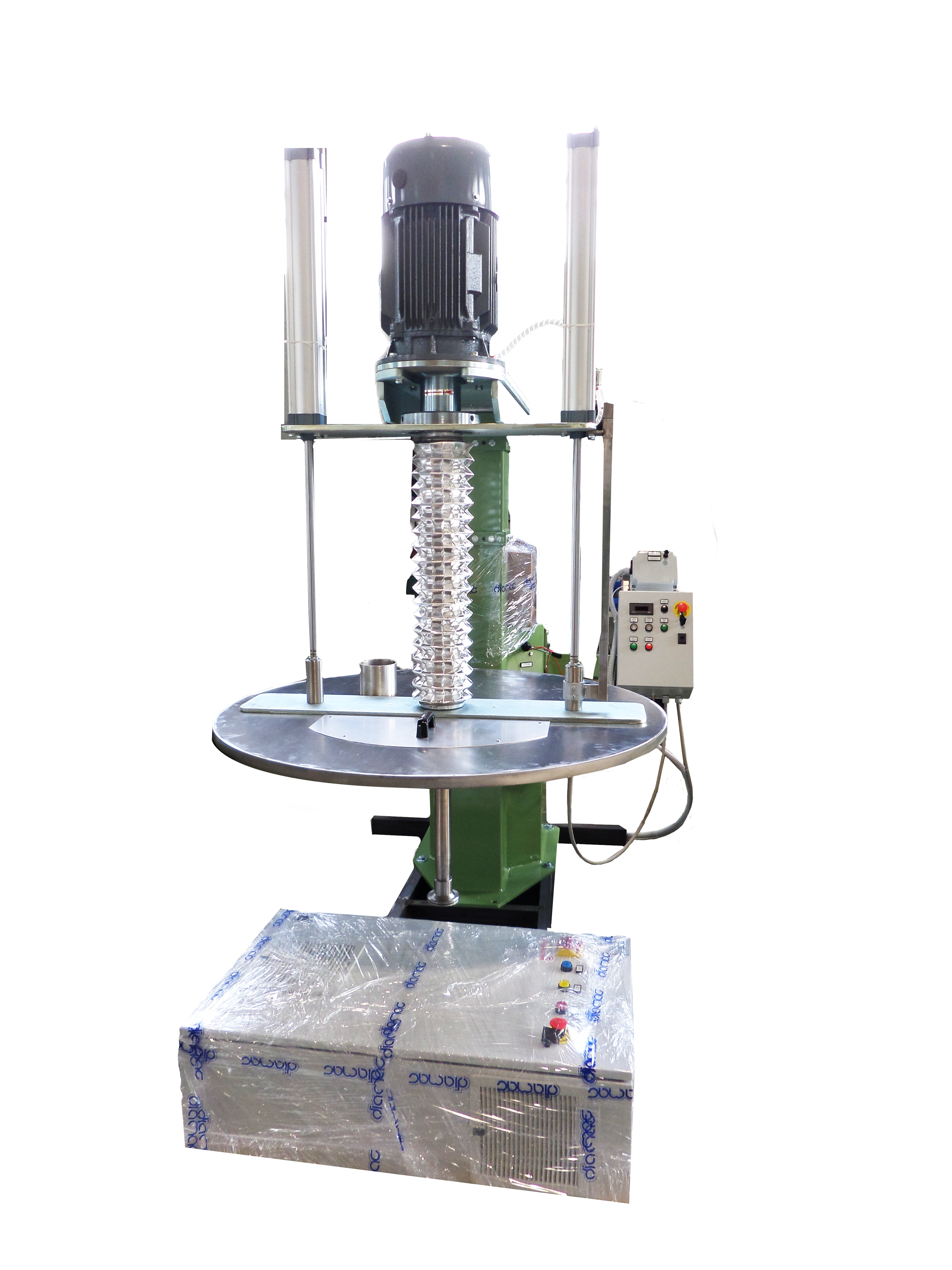

ELECTRONIC SPEED CHANGE STIRRERS

CONSTRUCTION FEATURES

- Metal structure

- Vessel locking unit adjustable with tightening belts

- "BELLOWS" safety, featuring rod supports, side sliding guides, stirring shaft bellows safety, and safety limit switch for placement of light-weight, removable lid.

- Hydraulic lifting with built-in power unit

- Lifting piston with check valves and flow control

- High-build chrome-plated stirring shaft

- Direct drive

- Cowless Aisi 304 stainless steel or chrome-plated impellers

- Switch board with Inverter control and disturbance filter

- disturbance filter

- Control panel of standard or explosion-proof type

- Heavy-duty or explosion-proof motor with thermistors

- Safety systems and CE mark

FUNCTIONS

All electronic controls and warning devices are placed on the disperser Control Panel.

The hydraulic-operated lifting distributor is located on the machine body: it must be operated together with the ON switch of the hydraulic unit motor on the Disperser control panel.

The Control Panel also includes: the potentiometer for stirring shaft speed adjustment, digital rev-counter with display, the ON - OFF - RESET push-buttons for Inverter and EMERGENCY button control.

The Switch board with the Inverter features the following controls: Powerswitch to set the machine on; thermal cut-out, mains voltage, thermistor protection lights; emergency button.

OPERATION AND MAINTENANCE

- Low energy consumption: power consumption depends on the power actually supplied by the Inverter by setting the power-knob

- Low noise

- Easily accessible and easy-to-use controls

- Easily replaceable vessels even with different diameters

- All main components are surface-mounted

- Easy access to the control unit, through back plate removal

ALTERNATIVE VERSIONS

- Version without Inverter with gearmotor with handwheel on the unit head.

- Version without Inverter with double speed motor, depending on user's power demand.

- Lower bearing column (3000 mm instead of 3500 mm)

- Longer motor supporting head for greater distance between the lifting piston and the stirring shaft.

- Automatic lifting control, during working cycle, with P.L.C. inside the control panel with inverter for a constant, adjustable and timed vertical machine movement to meet all user's needs.

- 2, 4, 6 and 8 pole motor

- Motor cooling with servoventilation

- Pneumatic piston, with dedicated switch, for vessel locking available in the standard version

- Lenard (propeller, tilted blades or anchor) impellers